Dashboard

The page provides information on the system. (Fig. 42)

When the EYE+ XTD Controller is not in production, the dashboard view is mainly empty. The content of this page is automatically populated as soon as production starts.

Fig. 42 DASHBOARD when system state is not production

Production dashboard

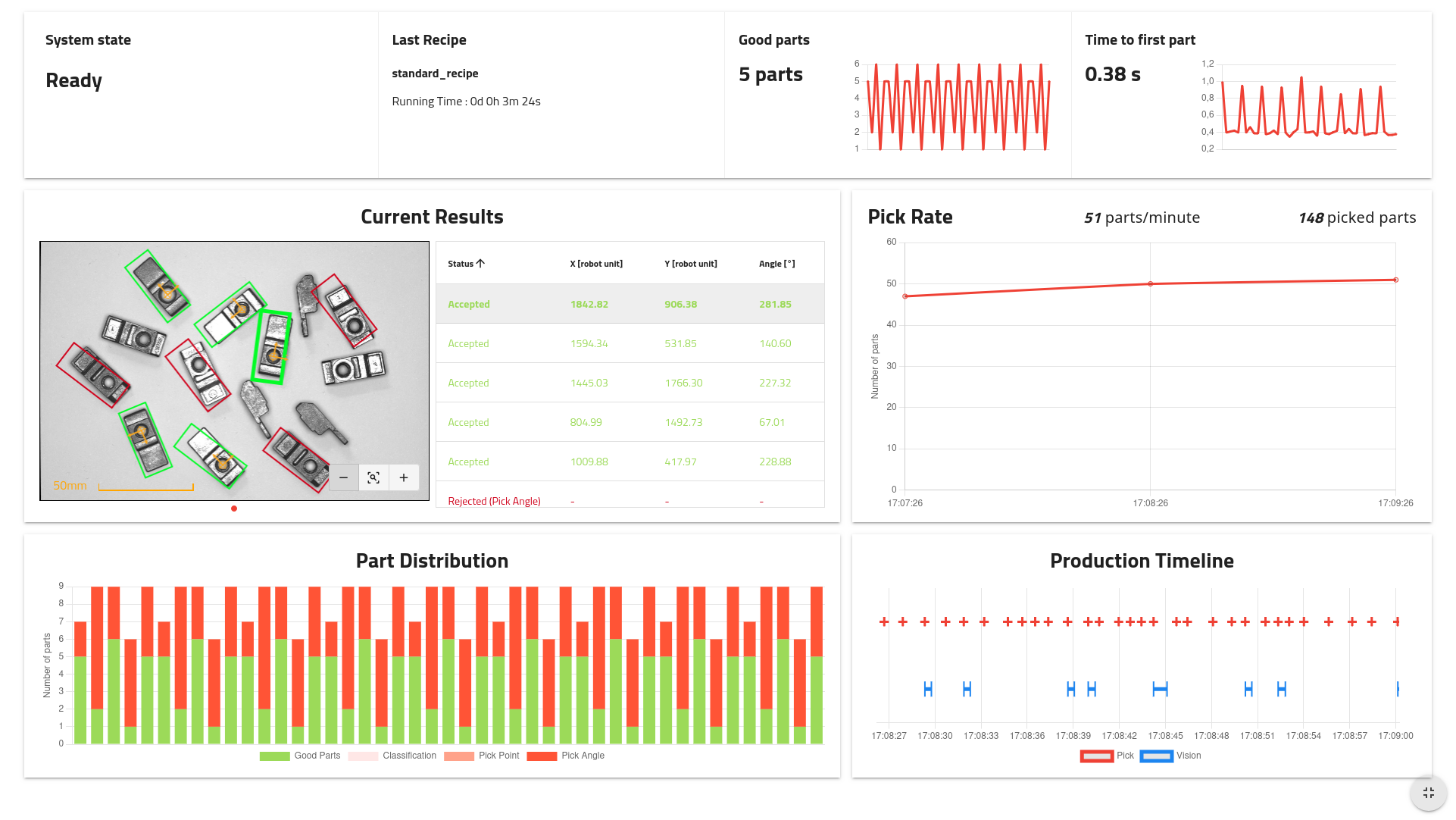

If the EYE+ XTD state is production, the dashboard (Fig. 43) displays some information about the current production.

Fig. 43 Production dashboard

Note

The information is displayed in real time but is not permanently saved on the EYE+ XTD Controller. When stopping the production, the latest data will still be visible but will be discarded when refreshing the interface.

Tip

Clicking on the small button on the bottom right opens the interface in full screen mode which ensures you can see the complete dashboard on an HD screen.

Upper area

Fig. 44 Production dashboard: Upper area

The upper area displays global information about the current production and is divided into 5 areas:

System state: Current EYE+ XTD state. Most of the information is displayed only when in production.

Recipe: Name of the recipe currently in production and elapsed time since the start of production.

Good parts: Number of good parts detected during the last image analysis. The chart shows the evolution of this value over the last 50 image analysis.

Time to first part: Time the system took to find the first part during the last image analysis. The chart shows the evolution of this value over the last 50 image analysis.

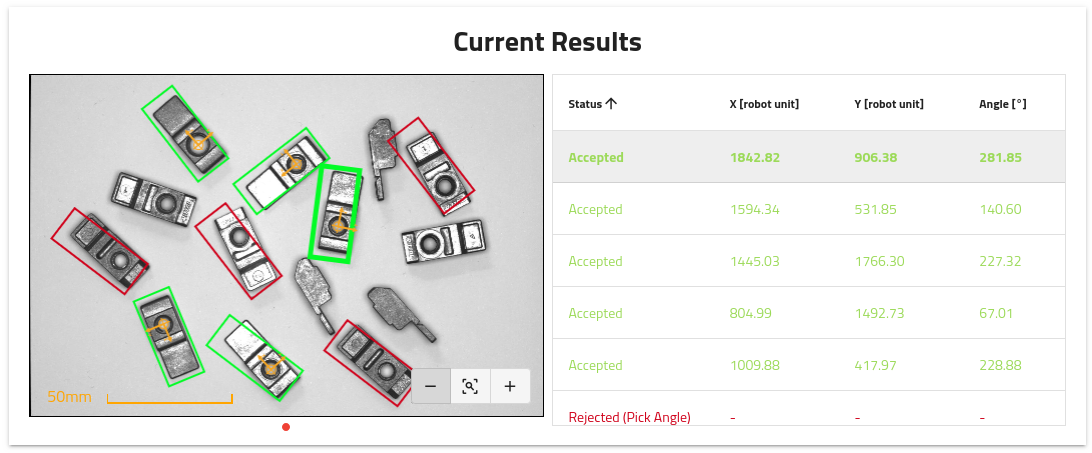

Current Results

Fig. 45 Production dashboard: Current Results

Displays the results of the latest analysis. You can navigate between the different images using the navigation dots below the image.

On the right, the list of candidates with their status (accepted or rejected), position coordinates (in robot unit) and angle is displayed. You can click on the lines in the table to highlight the desired part on the left image.

Tip

It is possible to export either the original full resolution image or the image with the overlay by right-clicking on the image area.

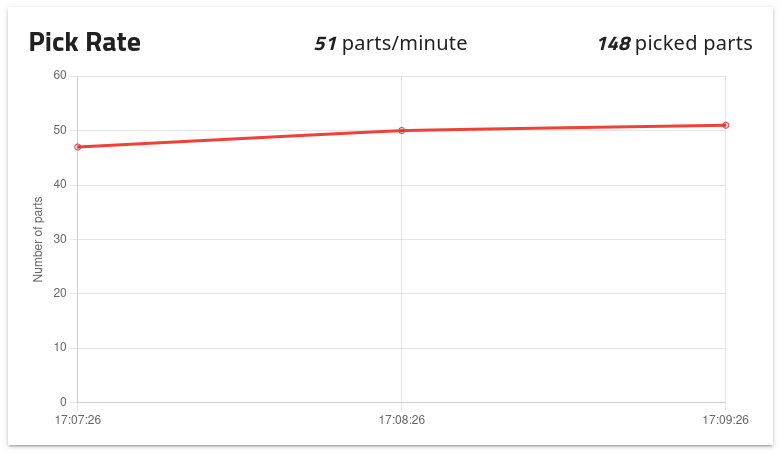

Pick Rate

Fig. 46 Production dashboard: Pick Rate

The graph displays the pick rate, calculated based on the number of get_part requests per minute. Above the graph, you can see:

Part/minute: The real-time number of parts picked per minute.

Picked Parts: The cumulative number of parts picked since the beginning of the current production run.

These insights help monitor system performance and identify potential slowdowns or bottlenecks during operation.

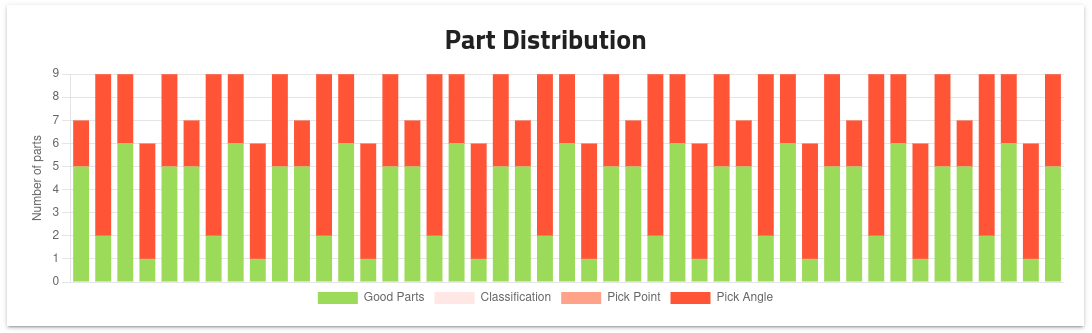

Part Distribution

Fig. 47 Production dashboard: Part Distribution

The chart plots the distribution of the parts between accepted and rejected over the last 50 image analysis.

Note

The total number of parts may not always correspond to the actual number of parts on the platform as only those detected by the EYE+ XTD vision algorithm (both good and bad candidates) can be counted.

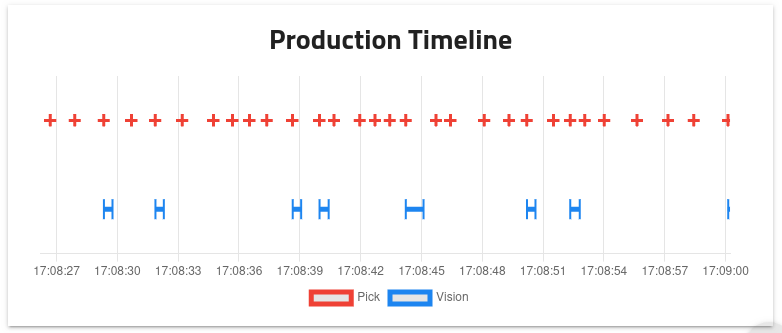

Production Timeline

Fig. 48 Production dashboard: Production Timeline

The production timeline summarizes the events that occurred in the last two minutes of the current production run. The top line represents the robot picks (response to a get_part), the middle one the vision analysis.

Note

If you want to create your own dashboard and integrate elements from the EYE+ XTD Studio dashboard, have a look at Integrate EYE+ XTD Studio dashboard.