2. Runs

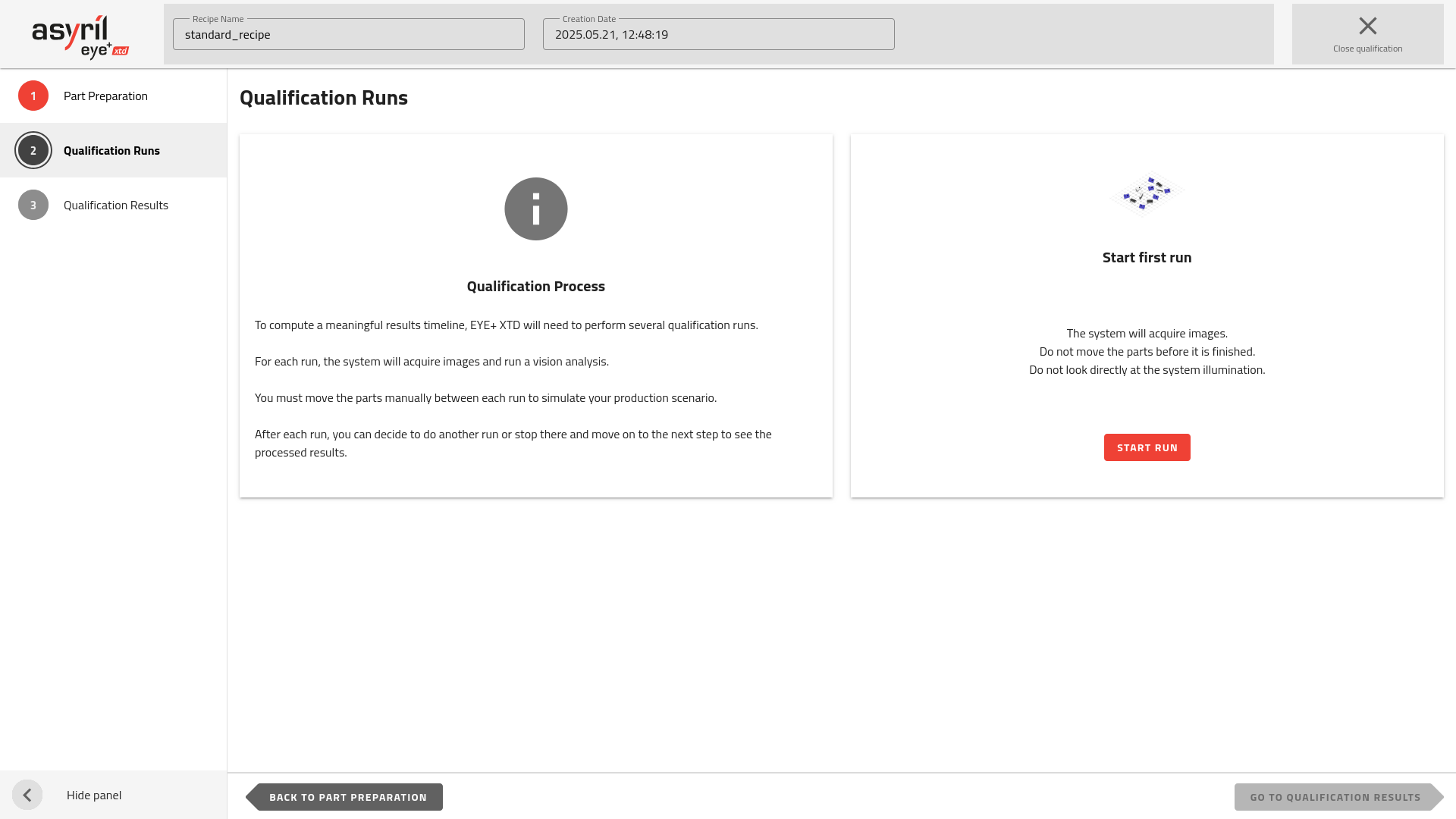

Fig. 116 Starting the first run

This next page lets you start the first run of the qualification process. After each run has been completed, you may choose between starting another one and finishing up the whole process.

For each run, the system collects information including the number of good parts found (displayed in the interface), as well as the execution timing of all actions performed by the system (vision analysis…).

Note

The more runs you perform, the more accurate the resulting data. We recommend you do at least 10 runs (max is 50), that will ensure the total number of parts found is statistically high enough for the results to be meaningful.

Important

Once a run is complete, remember to manually move the parts or replace them with another batch to simulate the production process. Try to make it look as similar to a real production run as possible.

Once the system completes a run, the following page will be displayed.

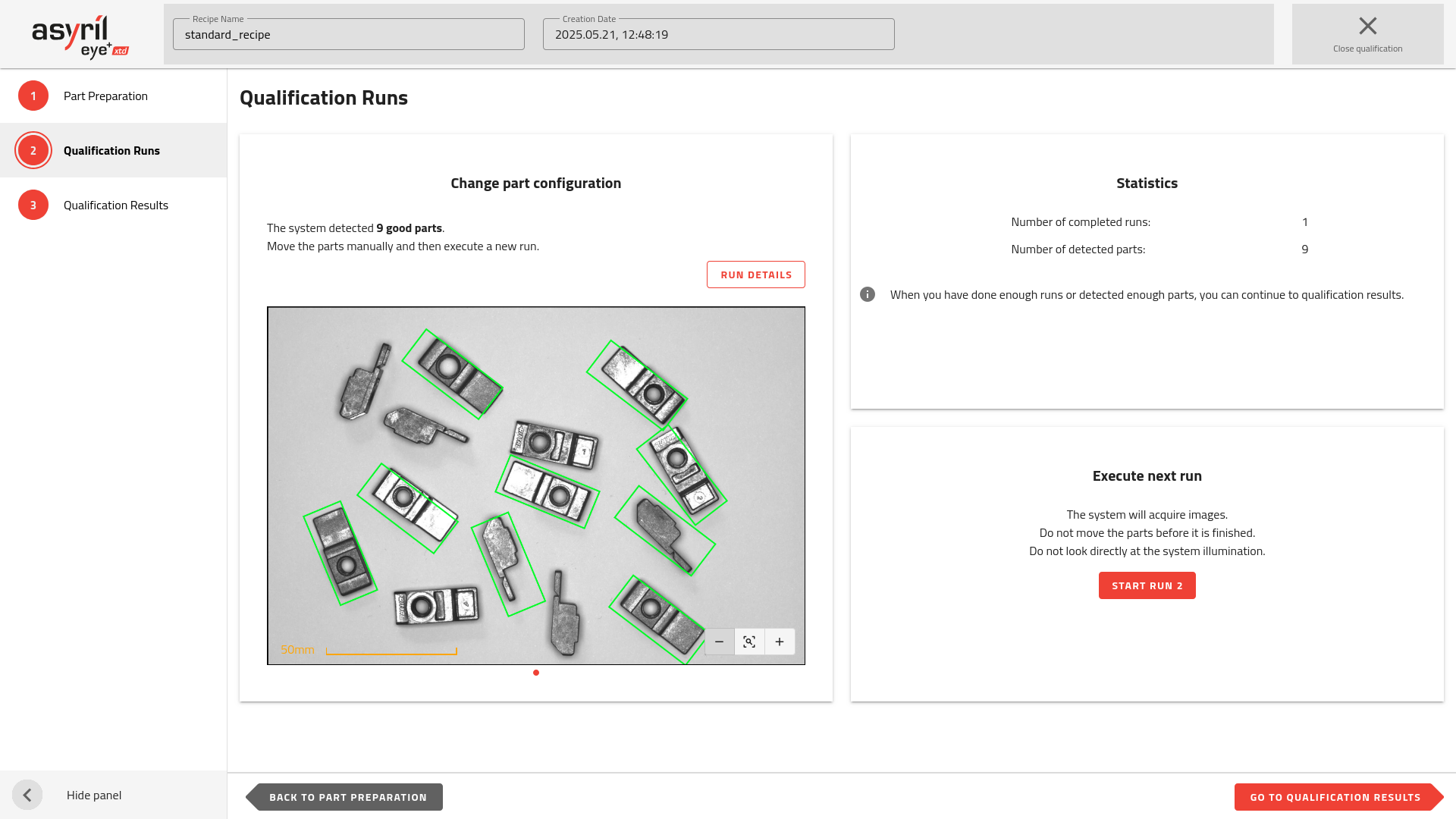

Fig. 117 Current run results

On the left side, you can see the results of the vision analysis (image(s) + number and bounding boxes of the good parts). The right side shows statistics about the current qualification process (all runs completed and total number of good parts found). This is also where you can start another run should you desire.

Tip

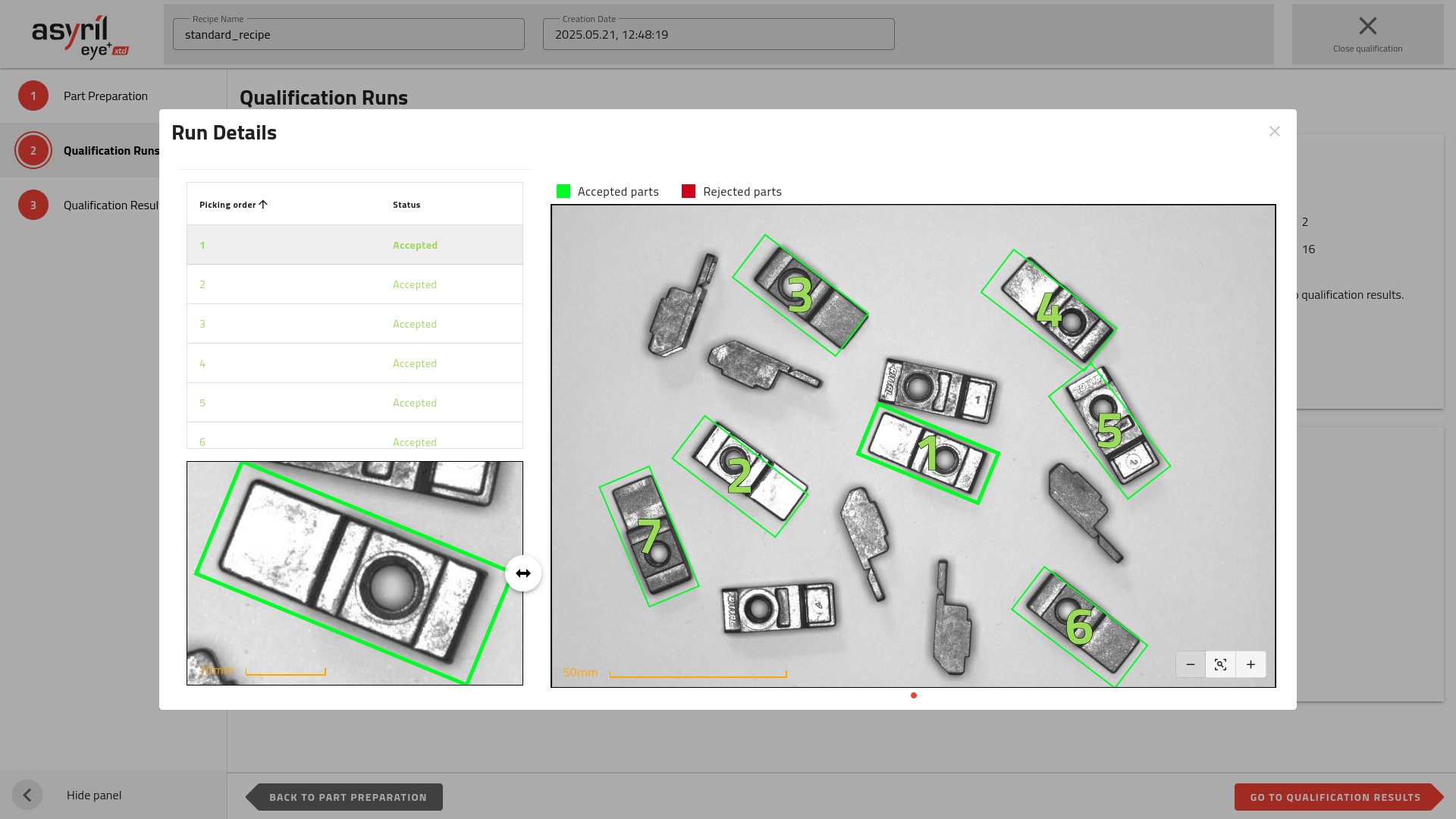

In case you would like to have more information about the results, you can click on to display a dialog with the results of the current run.

Fig. 118 Current run details